|

|

| Brand Name: | Winsamrt |

| Model Number: | SMTP300 |

| MOQ: | 1 set |

| Price: | USD1-10000/set |

| Packaging Details: | Plywood case |

| Payment Terms: | L/C, T/T, Western Union |

30T FR4 Aluminum PCB Punching Machine with Precision Punching Mold

PCB Punching Machine Overview:

The hydraulic PCB punching machine is the key to ensuring the normal and accurate operation of the machine. In order to ensure its normal operation and long service life, it is necessary to carefully assemble, test the machine, regularly inspect and have a good maintenance plan. In addition, special attention should be paid to the user's own usage conditions and working environment, which may affect the maintenance quality of this system. However, if no specific instructions are provided, users should strictly follow these instructions for installation, debugging, and use.

This hydraulic system consists of a pressure source pump group, a directional valve group, a filtration and cooling system, a control device, an oil tank, and pipelines.

During the working process, the filtration cooling system, control pump group, pressure source pump group, etc. are all controlled by electrical appliances. When the working flow of the vane pump in the pressure source pump group is output, the flow is supplied to each hydraulic component, and the electro-hydraulic valve (solenoid valve) group of the control cylinder is controlled by the electrical device to complete the back and forth movement of each cylinder.

The movement position of the hydraulic cylinder is controlled by a travel switch device.

PCB Punching Machine Features:

1. Depaneling PCBA with molds which can avoid tin cracking caused by hand folding.

2. Multiple molds are replaceable.

3. Easy to replace molds.

4. Servo push pull down mold reduces labor intensity.

5. PCB loading and unloading is easy.

6. The operation process is lightweight and safe, and the machine is equipped with safety devices.

PCB Punching Machine Technical Parameters:

Driven: Hydraulic station + hydraulic cylinder

Power Supply: Phase 3, 380VAC 50HZ

Output: 25 Ton

PCB Size: 400*400MM

Working Mode: Servo motor push-pull in and out for the lower mold

Machine Dimension: 1400(L)x985(W)x1750(H)MM

Weight: 850KG

PCB Punching Machine Specification:

| Working area | 400*400mm |

| Working pressure | 0.45-0.7Mpa |

| Cutting precision | ±0.05mm |

| Cycle time | 7-15 seconds |

| Output | 25T |

| PCB/FPC thickness | 0.08-3.5MM |

| PCB/FPC material | FPC, FR1, FR4, CEM-1, CEM-3, MCPCB |

| Cutting mode | Punching |

| Punch fixture | Die tooling(mold) |

| Working Property |

LCD display, Automatically records the number of processed products, automatic punching |

| Transmission port | International standard |

| Operation Language | English |

| Power | 380/220V |

| Fuse | 3A |

| Machine dimension | 1400x985x1750mm |

| Machine weight | 850kgs |

PCB Separator Punching Machine Details:

1. Professional wiring.

![]()

2. English language:

![]()

3. Password protection to avoid mis-operation.

![]()

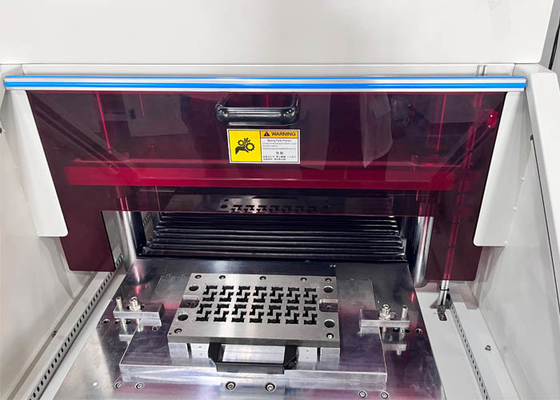

4. Customized punching mold for precise cutting, ESD drawer for easier PCB collection.

![]()

5. Double "Start" and safe door with sensor design to ensure safe production.

![]()

PCB Punching Machine Mold Dis-assembly and Installation:

Step 1: Move lower mold to the punching location by touch screen.

Step 2: Lower the upper mold to align well with lower mold.

Step 3: Loosen 8 screws of upper mold.

Step 4: Move the whole mold to the picking location by touch screen.

Step 5: Loosen 2 screws of lower mold.

Step 6: Remove the old mold.

Step 7: Put the whole mold on the origin location.

Step 8: Lock 2 screws to fix lower mold.

Step 9: Move the whole mold into the punching location.

Step 10: Lower the upper mold base to align upper mold.

Step 11: Loosen 8 screws to fix upper mold.

Step 12: Installtion is finished.

![]()

![]()

PCB Punching Machine Maintenance:

1. Timely clean up debris

2. Regularly (1 week) lubricate the screw, guide rail, bearings, and moving parts with butter

3. If any organic components are damaged, please replace them in a timely manner

4. Do not stack materials between the heat dissipation holes and the heat dissipation fan, and maintain a certain distance

5. Maintenance instructions for hydraulic station

|

| Brand Name: | Winsamrt |

| Model Number: | SMTP300 |

| MOQ: | 1 set |

| Price: | USD1-10000/set |

| Packaging Details: | Plywood case |

| Payment Terms: | L/C, T/T, Western Union |

30T FR4 Aluminum PCB Punching Machine with Precision Punching Mold

PCB Punching Machine Overview:

The hydraulic PCB punching machine is the key to ensuring the normal and accurate operation of the machine. In order to ensure its normal operation and long service life, it is necessary to carefully assemble, test the machine, regularly inspect and have a good maintenance plan. In addition, special attention should be paid to the user's own usage conditions and working environment, which may affect the maintenance quality of this system. However, if no specific instructions are provided, users should strictly follow these instructions for installation, debugging, and use.

This hydraulic system consists of a pressure source pump group, a directional valve group, a filtration and cooling system, a control device, an oil tank, and pipelines.

During the working process, the filtration cooling system, control pump group, pressure source pump group, etc. are all controlled by electrical appliances. When the working flow of the vane pump in the pressure source pump group is output, the flow is supplied to each hydraulic component, and the electro-hydraulic valve (solenoid valve) group of the control cylinder is controlled by the electrical device to complete the back and forth movement of each cylinder.

The movement position of the hydraulic cylinder is controlled by a travel switch device.

PCB Punching Machine Features:

1. Depaneling PCBA with molds which can avoid tin cracking caused by hand folding.

2. Multiple molds are replaceable.

3. Easy to replace molds.

4. Servo push pull down mold reduces labor intensity.

5. PCB loading and unloading is easy.

6. The operation process is lightweight and safe, and the machine is equipped with safety devices.

PCB Punching Machine Technical Parameters:

Driven: Hydraulic station + hydraulic cylinder

Power Supply: Phase 3, 380VAC 50HZ

Output: 25 Ton

PCB Size: 400*400MM

Working Mode: Servo motor push-pull in and out for the lower mold

Machine Dimension: 1400(L)x985(W)x1750(H)MM

Weight: 850KG

PCB Punching Machine Specification:

| Working area | 400*400mm |

| Working pressure | 0.45-0.7Mpa |

| Cutting precision | ±0.05mm |

| Cycle time | 7-15 seconds |

| Output | 25T |

| PCB/FPC thickness | 0.08-3.5MM |

| PCB/FPC material | FPC, FR1, FR4, CEM-1, CEM-3, MCPCB |

| Cutting mode | Punching |

| Punch fixture | Die tooling(mold) |

| Working Property |

LCD display, Automatically records the number of processed products, automatic punching |

| Transmission port | International standard |

| Operation Language | English |

| Power | 380/220V |

| Fuse | 3A |

| Machine dimension | 1400x985x1750mm |

| Machine weight | 850kgs |

PCB Separator Punching Machine Details:

1. Professional wiring.

![]()

2. English language:

![]()

3. Password protection to avoid mis-operation.

![]()

4. Customized punching mold for precise cutting, ESD drawer for easier PCB collection.

![]()

5. Double "Start" and safe door with sensor design to ensure safe production.

![]()

PCB Punching Machine Mold Dis-assembly and Installation:

Step 1: Move lower mold to the punching location by touch screen.

Step 2: Lower the upper mold to align well with lower mold.

Step 3: Loosen 8 screws of upper mold.

Step 4: Move the whole mold to the picking location by touch screen.

Step 5: Loosen 2 screws of lower mold.

Step 6: Remove the old mold.

Step 7: Put the whole mold on the origin location.

Step 8: Lock 2 screws to fix lower mold.

Step 9: Move the whole mold into the punching location.

Step 10: Lower the upper mold base to align upper mold.

Step 11: Loosen 8 screws to fix upper mold.

Step 12: Installtion is finished.

![]()

![]()

PCB Punching Machine Maintenance:

1. Timely clean up debris

2. Regularly (1 week) lubricate the screw, guide rail, bearings, and moving parts with butter

3. If any organic components are damaged, please replace them in a timely manner

4. Do not stack materials between the heat dissipation holes and the heat dissipation fan, and maintain a certain distance

5. Maintenance instructions for hydraulic station